| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | HARTING |

| Manufacturer Part Number: | HARTING 09110006230 |

| Gender: | Female |

| Series: | TC 70 |

| Wire Size: | 6 mm² |

| Mating Cycles: | 500 cycle |

| Contact Design: | Machined |

| Current Rating: | 70 A |

| Contact Plating: | Silver |

| Contact Material: | Copper Alloy |

| Stripping Length: | 15 mm |

| Contact Resistance: | .5 mΩ |

| Termination Method: | Crimp |

| Maximum Operating Temperature: | 125 °C |

| Minimum Operating Temperature: | -40 °C |

| SKU: | HRT09110006230 |

09110006230

Specifications

Detailed Description

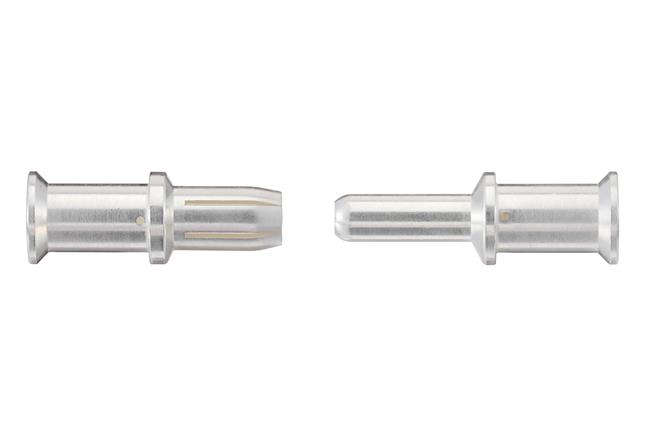

Introducing the 09110006230, a high-performance TC 70 Crimp Contact designed for seamless connectivity in demanding environments. This female contact boasts a robust construction using copper alloy with silver plating, ensuring excellent conductivity and corrosion resistance. With a maximum operating current of 70A and a conductor cross-section of 6mm², it is suitable for power-intensive applications. Engineered for reliability, this contact offers a low contact resistance of .5 mΩ and can withstand up to 500 mating cycles. Its machined design guarantees precision and consistency in connections. Operating efficiently in temperatures ranging from -40°C to 125°C, this RoHS-compliant contact is ideal for various industrial and commercial uses. With a stripping length of 15mm, it facilitates easy installation. Trust in the 09110006230 for secure and efficient wire termination in your projects.

Frequently Bought Together

| Product | Part # | Description | Stock |

|---|---|---|---|

| HARTING 09110006132 | Crimp contact, male, 16 MM2 |  |

| HARTING 09140013073 | HAN PE-MODULE MALE CRIMP 25QMM |  |

| HARTING 09140060361 | Han-Modular®, Hinged frame, for 2 modules, A ... B; Size: 6 B |  |

| HARTING 09300060543 | Hoods, 6 B, aluminium die-cast, powder-coated, IP65 |  |

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 02/29/2024 | PCN23-012CN - Diameter Change. The outer diameter of the Han® TC70 contacts 2.5 – 16 mm² will be reduced from 11.5 mm to 11.0 mm on the termination side only. The outer diameter 11.5 mm on the mating side and all other dimensions remain the same. The modification has no impact on the product specification, handling and applications. | Download | |||

| 09/02/2022 | PCN22001CN-US - product change. Implementation of a radius to the end of the inlet funnel of the crimp hole. This change optimizes handling in the crimping process. | Download | |||