| Attribute | Value |

|---|---|

| Product Category: | |

| Manufacturer: | HARTING |

| Manufacturer Part Number: | HARTING 09110006225 |

| Gender: | Female |

| Series: | TC 100 |

| Wire Size: | 25 mm² |

| Mating Cycles: | 500 cycle |

| Contact Design: | Machined |

| Current Rating: | 100 A |

| Contact Plating: | Silver |

| Contact Material: | Copper Alloy |

| Stripping Length: | 19 mm |

| Contact Resistance: | 0.3 mOhm |

| Termination Method: | Crimp |

| Maximum Operating Temperature: | 125 °C |

| Minimum Operating Temperature: | -40 °C |

| SKU: | HRT09110006225 |

09110006225

| ICC Number: | HRT09110006225 |

| Manufacturer: | HARTING |

| Manufacturer Number: | 09110006225 |

| Datasheet: | Datasheet |

| ECAD Model: |

Description:

HARTING offers a large range of terminations technology for contacts: - Screw terminal - Crimp terminal - Axial screw terminal - Cage-clamp terminal - IDC (Insulation displacement terminal) - Han-Quick Lock® termination technique

More >>Specifications

Detailed Description

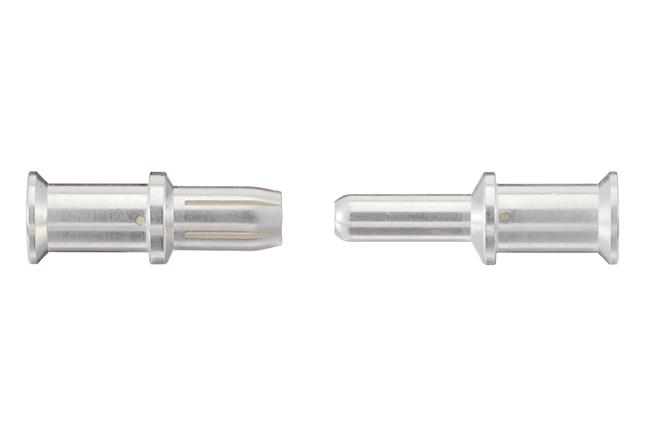

The HARTING TC 100 Female Crimp Contact is a high-performance termination solution for wire sizes up to 25mm². Constructed from durable copper alloy with silver plating, this contact ensures reliable conductivity in demanding environments, with a low contact resistance of 0.3 mOhm. Designed for longevity, it offers a mating cycle of 500, making it ideal for applications requiring frequent connections. With a current rating of 100 A and a wide operating temperature range from -40°C to 125°C, this contact is suitable for use in a variety of industrial settings. RoHS compliant and featuring a machined contact design, it guarantees both performance and environmental responsibility. Individually packaged and available for immediate shipping, the HARTING TC 100 Female Crimp Contact is the perfect choice for high-power, high-reliability applications.

Frequently Bought Together

| Product | Part # | Description | Stock |

|---|---|---|---|

| HARTING 09110006125 | Crimp contact, male, 25 MM2 |  |

| HARTING 09110006133 | Crimp contact, male, 25 MM2 |  |

| HARTING 09140013131 | Han® 100 A Single module, female, 1 contacts, 100 A, 830 V |  |

| HARTING 09140013173 | HAN PE-MODULE FEM. CRIMP 25QMM |  |

| HARTING 09140023051 | Han® 100 A module, male, 2 contacts, 100 A, 1000 V |  |

| HARTING 09140023151 | Han® 100 A module, female, 2 contacts, 100 A, 1000 V |  |

| HARTING 09140160361 | Han-Modular®, Hinged frame, for 4 modules, A ... D; Size: 16 B |  |

| HARTING 09150006104 | Crimp contact, male |  |

| HARTING 09320006108 | Crimp contact, male, 6 MM2 |  |

| HARTING 09380062701 | insert, Size: 16 B, female, 80 A, 830 V |  |

| HARTING 19000005098 | Cable gland, Size: M40, Material: Metal |  |

Product Change Notice

| Effective Date | Description of Change | Download | |||

|---|---|---|---|---|---|

| 09/02/2022 | PCN22001CN-US - product change. Implementation of a radius to the end of the inlet funnel of the crimp hole. This change optimizes handling in the crimping process. | Download | |||