02011602101

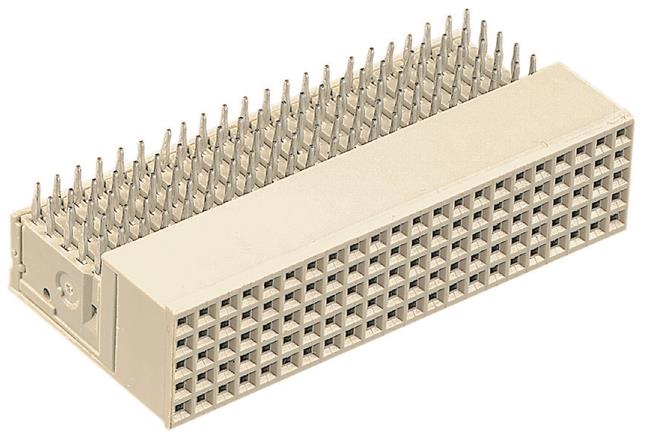

har-bus® 64, Connector; Male connector; LCP; Motherboard to daughtercard, Extender card; Reflow soldering termination (THR/SMC); Rated current: 1A

The har-bus® 64 Connector ( 02011602101) is a male LCP connector designed for reliable motherboard to daughtercard and extender card connections. With a reflow soldering termination (THR/SMC) method, this connector ensures secure attachment. Featuring 160 contacts in a 5-row configuration, it offers ample connectivity with a pitch of 2.54mm. Constructed with Liquid Crystal Polymer housing and tin over nickel contact plating, it guarantees durability and efficient signal transmission. Rated for 1A current and 1kV voltage, this connector operates flawlessly in a wide temperature range from -55°C to 125°C. With RoHS compliance and 250 mating cycles, it meets industry standards for reliability and environmental responsibility, making it ideal for backplane and board-to-board applications.

Details

| Product Category: | |

| Manufacturer: | HARTING |

| Manufacturer Part Number: | HARTING 02011602101 |

| Series: | har-bus® 64 |

| Gender: | Male |

| Housing Material: | Liquid Crystal Polymer |

| Number of Contacts: | 160 |

| Number of Rows: | 5 |

| Termination Method: | Solder |

| Contact Plating: | Noble Metal Over Nickel, Tin Over Nickel |

| Maximum Operating Temperature: | 125 °C |

| Minimum Operating Temperature: | -55 °C |

| Pitch: | 2.54 mm |

| Mount Angle: | Right Angle |

| Mating Cycles: | 250 cycle |

| Performance Level: | Class II |

| Current Rating: | 1 A |

| Voltage Rating: | 1 kV |

| SKU: | HRT02011602101 |

Frequently bought together

Compliance

Environmental Initiative Details

| Environmental Initiative: | RoHS |

|---|---|

| Compliant: | Unknown |

| Date of this Information: | Unknown |

| Notes: |

Product Change Notice

Product Change Notice

| Effective Date | Description of Change | Download |

|---|---|---|

| 06/01/2022 | PCN21-030-PMMDUS - Plating Optimization. Due to the global cost impacts to noble metals such as palladium, we would like to inform you of plating optimizations that will be made to our DIN BC product portfolio. Part of this optimization is the implementation of nickel-phosphor plating – a surface that has been tested in the industry for decades. | Download |